ATEX

We deliver proven solutions

Where it is essential to use certified products that meet strict safety standards. Our portfolio includes a wide range of products – from intercoms and lighting to complete electrical systems – designed for use in ATEX zones 1, 2, 21, and 22. We present a selection from our portfolio. Choose specific products and access detailed information including technical specifications, documentation, and possible solutions.

Intercom:

ATEX intercom

Lighting:

- RINO-EX OVAL BULKHEAD LAMP IN ALUMINIUM ALLOY 18W IP65 3D

- RINO-EX STAINLESS STEEL AND GLASS LIGHTING FIXTURE 1×18W WITH WHITE REFLECTOR AND ELECTRONIC POWER SUPPLY 2D 2G

- XTIGUA-EX FLOODLIGHT 48 LED 201W ASYMMETRICAL OPTIC 23°, IP66, 3G 2D

- META S – INDUSTRIAL SUSPENDED ATEX LIGHT 18 LED, ROTOSYMMETRICAL WIDE OPTIC, GLASS, IP66/IP67 – ZONE 22

Electrical Systems:

- TAISBOX-EXU ENCLOSURE IN GRP (glass-reinforced plastic) 92×92×100, EX CATEGORY 2D 2G

- UNIBOX-EX ENCLOSURE IN ALUMINIUM UNI B9 100×100×59, EX CATEGORY 3G 3D

- TAIS-EX INTERLOCKED SOCKET IN GRP (glass-reinforced plastic), ATEX 2P+E 16A 110V 4H, IP66/67, EX CATEGORY 2D 3G

- XCEE-EX STRAIGHT PLUG 2P+T 16A 110V 4H, IP66/67, EX CATEGORY 3G 2D

ATEX environment

We bring to the market products with proven experience in extreme environments where flammable materials, oxidizing chemicals, salt solutions, acids, or motor and vegetable oils are handled. We are a supplier of top-tier ATEX products and explosion-proof equipment designed for high-risk environments. Power plants, the chemical industry, oil platforms, military bases, and refineries are just some of the areas where electrical installation and lighting equipment must prevent the spread of sparks and ensure long-term safety and operational reliability.

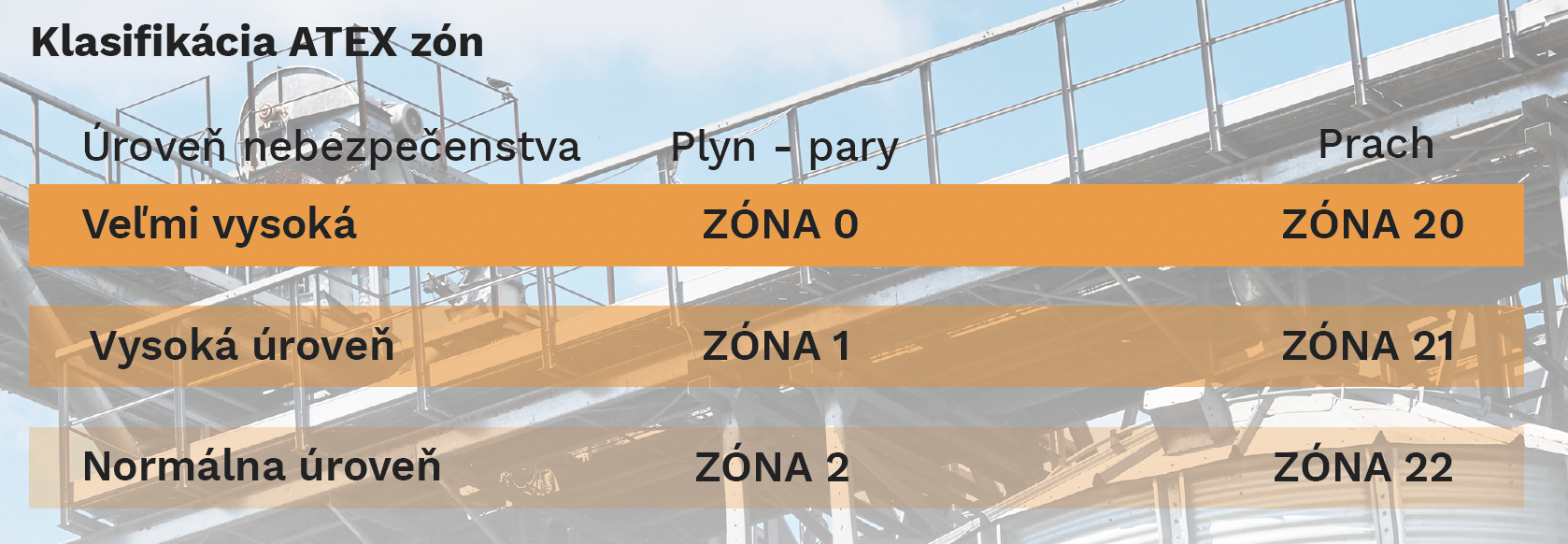

ATEX zone classification

ATEX zones define the level of explosion hazard in industrial environments. The classification includes three levels:

- Zone 0 (gas, vapors) and Zone 20 (dust) – a hazardous atmosphere is present permanently or for extended periods.

- Zone 1 (gas, vapors) and Zone 21 (dust) – a hazardous atmosphere occurs occasionally during normal operation.

- Zone 2 (gas, vapors) and Zone 22 (dust) – a hazardous atmosphere occurs only briefly or in case of a malfunction.

Proper classification of zones is crucial for selecting suitable equipment and ensuring safety in hazardous environments.

European ATEX Directive 2014/34/EU

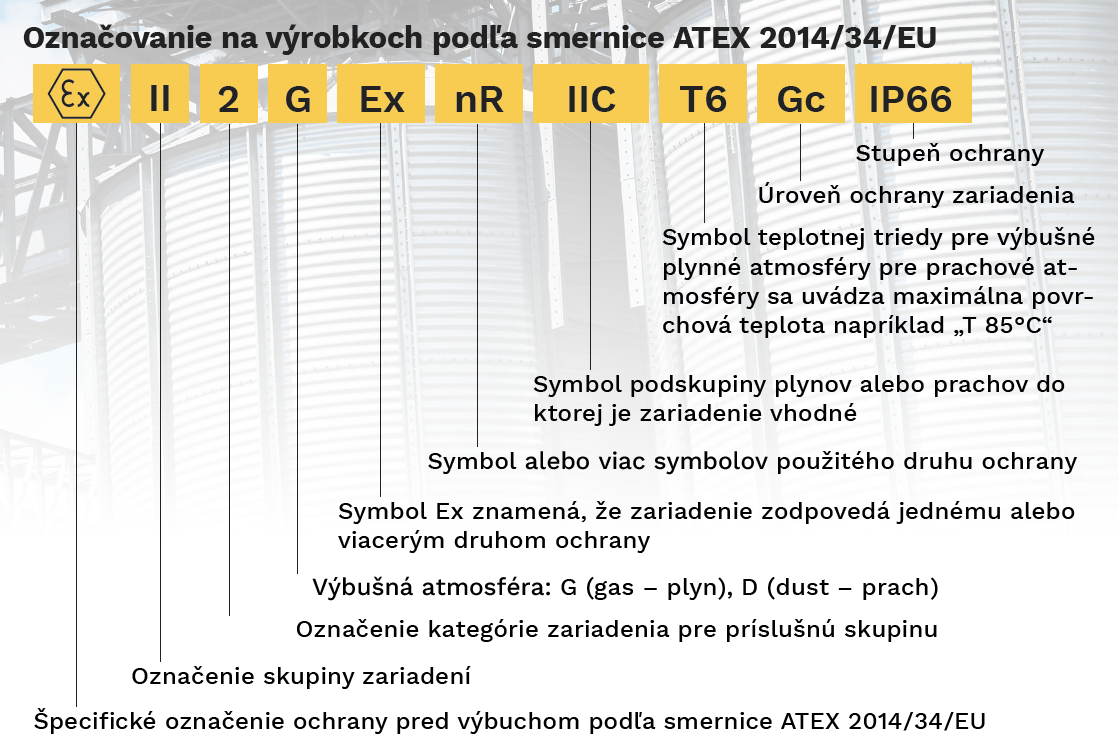

The ATEX Directive 2014/34/EU establishes rules for the marking of equipment intended for explosive environments. Each device must be labeled with a set of symbols that provide information about its safety features and suitability for a given environment.

European marking on ATEX products:

- Ex – Indicates that the equipment is intended for explosive atmospheres.

- II – Equipment group (II = industrial use, I = mining environment).

- 2 – Equipment category (1 = very high protection, 2 = high protection, 3 = normal protection).

- G – Type of explosive atmosphere (G = gas, D = dust).

- Ex – Confirms that the equipment meets explosion protection requirements.

- nR – Type of protection (e.g., "nR" denotes non-sparking equipment).

- IIC – Gas or dust group (e.g., IIC = hydrogen, acetylene – the most hazardous group).

- T6 – Temperature class (e.g., T6 = max. surface temperature of 85°C).

- Gc – Equipment protection level (e.g., "Gc" means high safety level).

- IP66 – Ingress protection rating (e.g., IP66 indicates complete protection against dust and strong water jets).

Importance of ATEX labeling

This marking is essential for the safety of industrial applications in explosive environments. Proper classification ensures compliance with regulatory standards and reduces the risk of explosive atmospheres.

Are you interested in a custom-made solution?

Are you in need of a complete infrastructure in your newly-built premises?